Bending sheet metal involves a large amount of force (calculated by tonnage), and to accomplish and produce this drive, the punch is lowered onto the sheet metal via many distinctive approaches. In software, there are several different types of press brake engineering, which include:

TRUMPF bending machines signify a prosperity of expertise and revolutionary innovation. The extensive portfolio contains machines for die and panel bending systems and also significant structure bending machines and fully automatic solutions. There is a wide array of choices readily available for each bending technology to suit your distinct software.

The body from the press brake serves as the muse to the set up of hydraulic factors, Together with the oil tank integrated in the stamping body.

High-quality Look at: Last of all, each individual bent piece undergoes a radical inspection to verify it meets all the specified angles and Proportions.

In a minimal, the smallest bend radius needs to be a minimum of equivalent to the sheet thickness to stay away from fractures or distortions while in the metal portion.

In the many years, SweBend has developed and refined various functions and updates to create our machines as Electrical power effective as you possibly can, and we continually strive to steer a constructive environmental route throughout the business.

Hence, an allocation must be built for these incidence by bending the fabric slightly previously mentioned the specified posture.

Even though steel may perhaps require warmth remedy for more intricate operations, it is still much easier to get the job done with in comparison to stainless-steel. Delicate steel, in particular, is pretty simple to shape.

That can assist you make the most of sheet metal fabrication, we set together this complete industrial bending equipment manual to the basics of this technique that may assistance you choose whether it is the best option on your undertaking and create best metal elements. Down load Subscribe Our Newsletter

One more very similar principle is corner relief; it is the length that needs to be cut out at the Conference position of the bent line. So, for the corners, you should consider a cut-out for his or her perfect alignment and steer clear of material tearing.

This information will check out the importance of sheet metal bending, its value in sheet metal fabrication processes, and how to bend sheet metal. What's more, it incorporates some handy bending tips which often can guide on bending metal plates.

We only use examined, field common and foreseeable future proof factors. In the end we guarantee the best quality by preserving our manufacturing and assembly in-house and making use of environment-renowned Swedish manufacturing standards.

To assist you to take advantage of of sheet metal fabrication, we set alongside one another this comprehensive manual to the fundamentals of This system that could help you select whether it is the best choice on your task and generate best metal elements. Down load The rise within the demand for tailor made-produced products resulted in exploration that proved sheet metal for being a versatile material which can be remodeled into distinct forms.

Advanced Stroke Regulate: The ram stroke is precisely managed via an advanced CNC system, with the capability for guide high-quality-tuning. A electronic counter display supplies real-time stroke data for Improved accuracy.

Ariana Richards Then & Now!

Ariana Richards Then & Now! Michael Bower Then & Now!

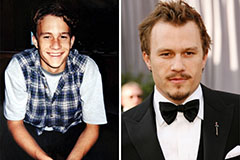

Michael Bower Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Katie Holmes Then & Now!

Katie Holmes Then & Now! Traci Lords Then & Now!

Traci Lords Then & Now!